Concrete investigations

How can you recognize damaged reinforced concrete??

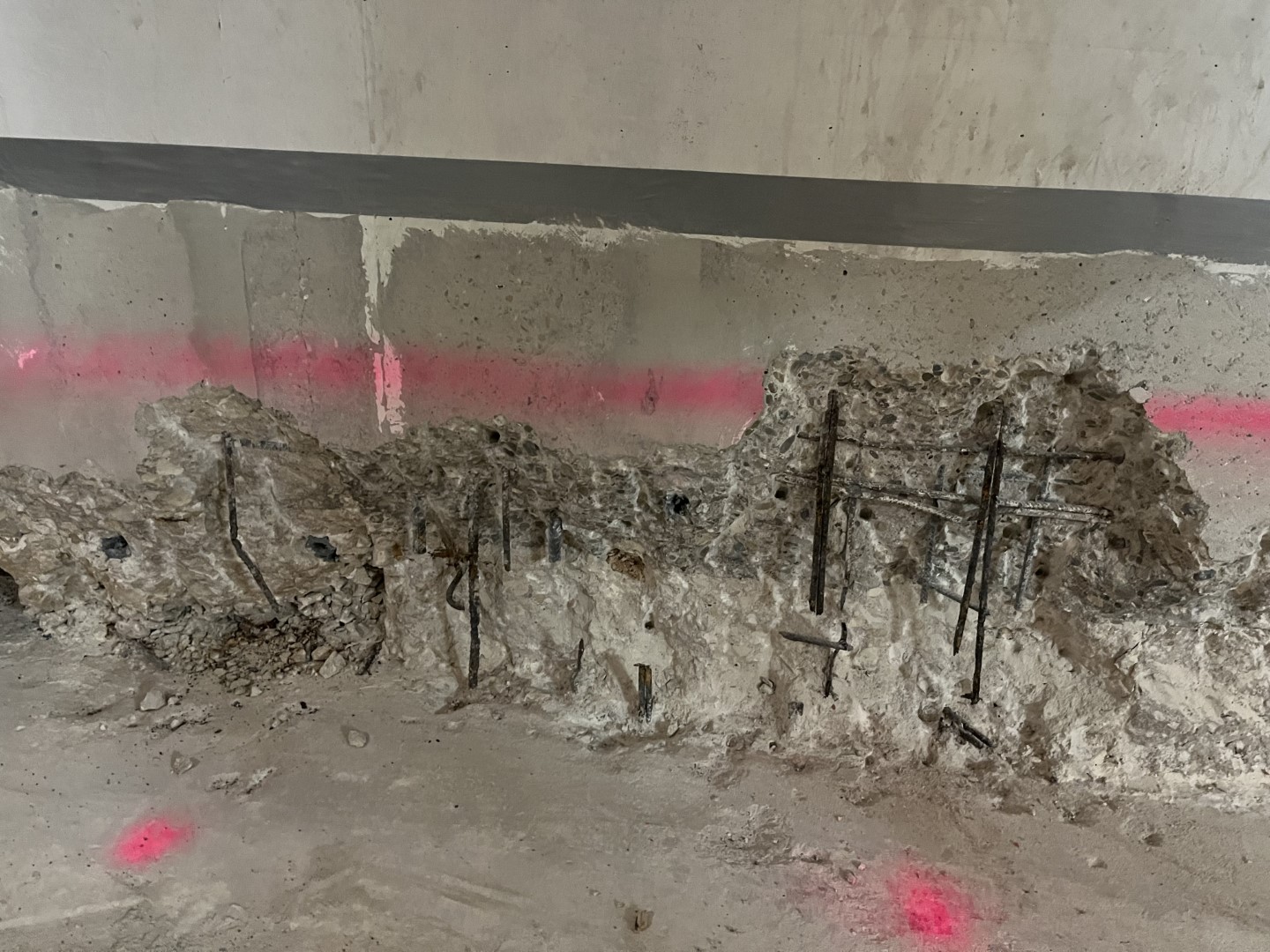

A shockingly high proportion of bridges, underground car parks and balconies in Germany show damage to load-bearing concrete components such as the star supports, floor slabs and foundations, which are often visually apparent in the form of cracks, spalling or visible damage indicate corrosion. These are a direct result of exposure to two chemicals that are transmitted in winter via splash water and also through the air.

Die Folge: Korrosion

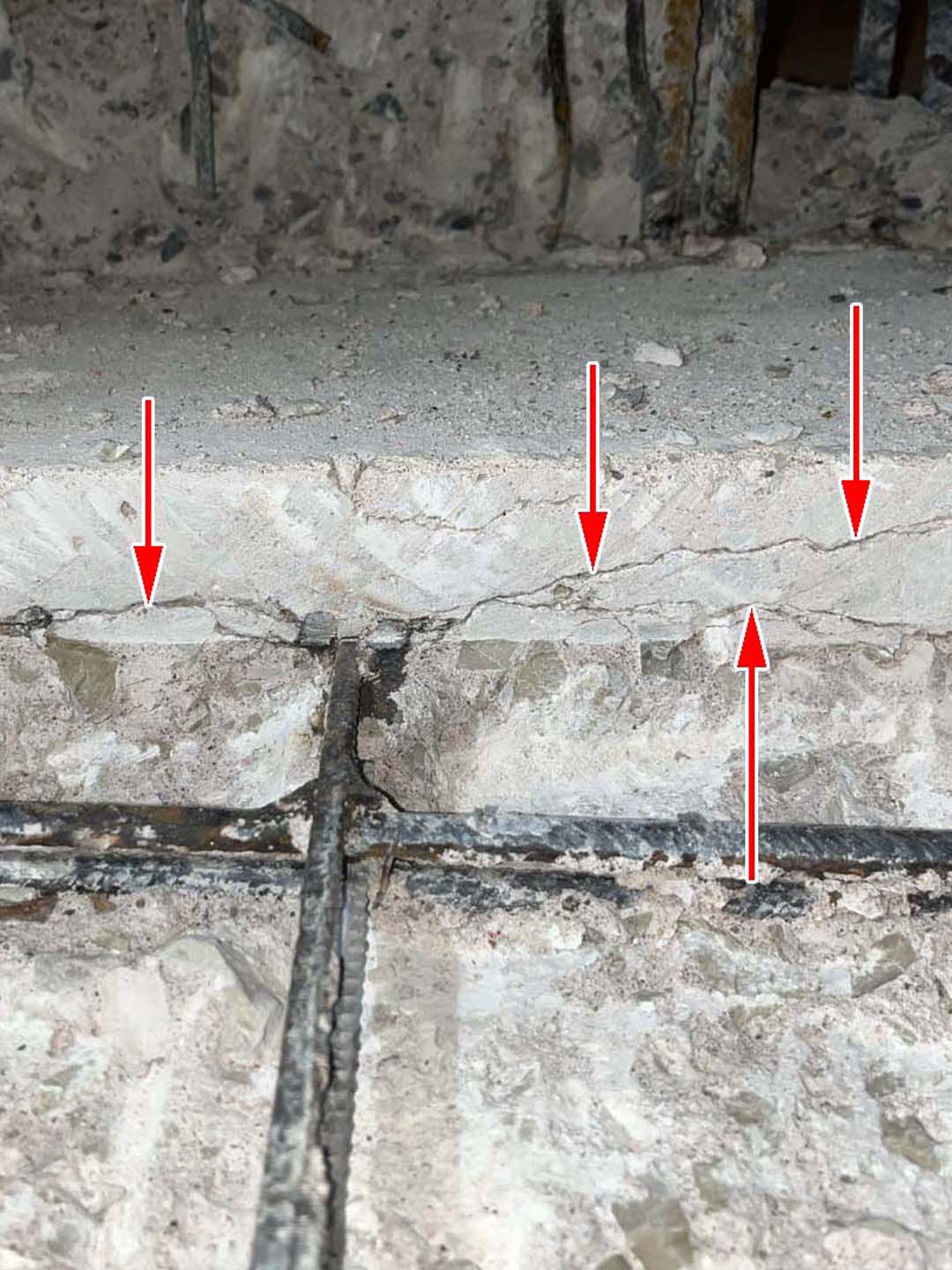

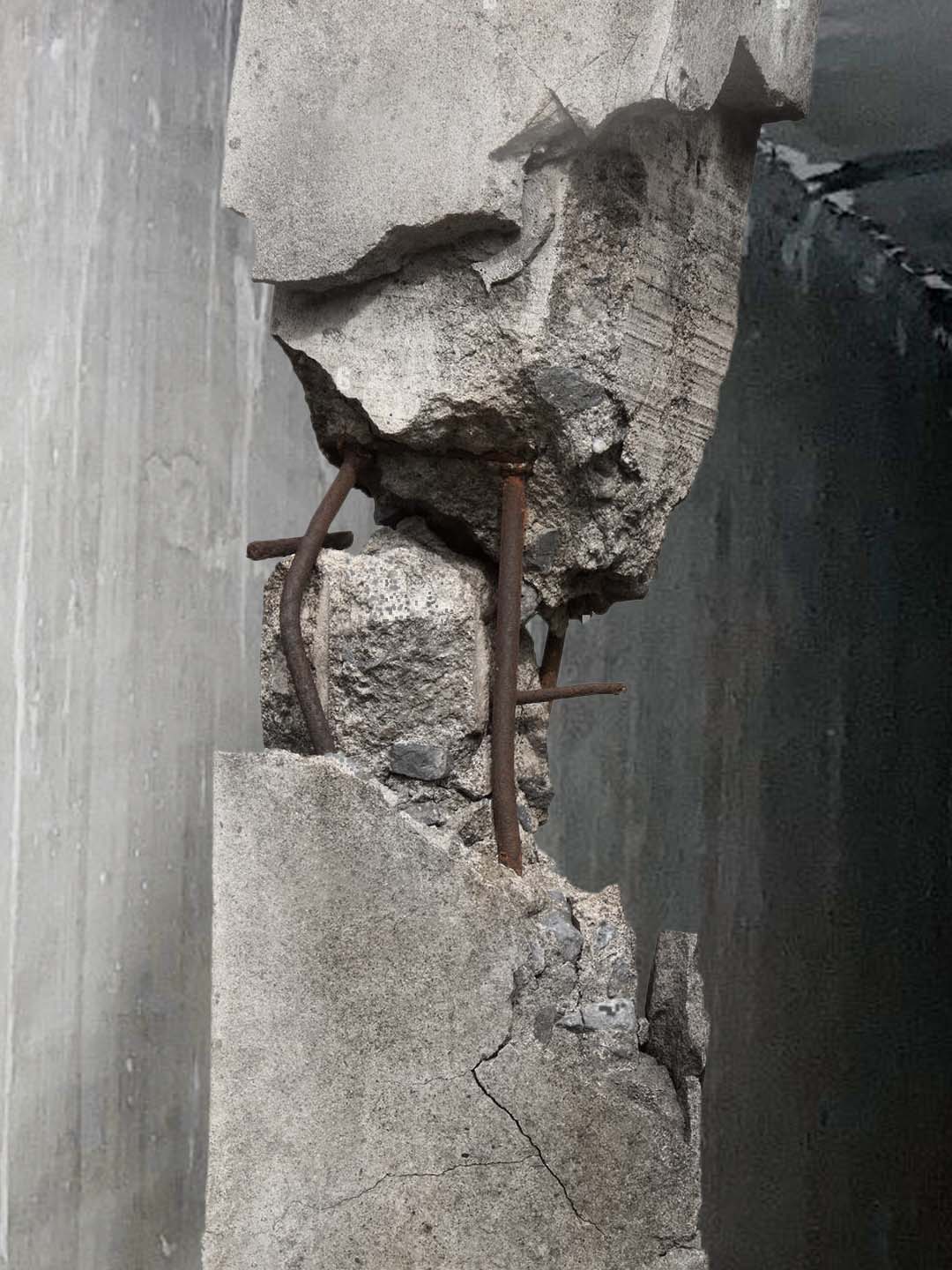

The chemical reactions remove the property of the concrete that protects the steel from corrosion and the reinforcing steel begins to rust or completely dissolve, meaning that the load-bearing capacity is no longer guaranteed. Where reinforcing steel is actually supposed to absorb the tensile forces, in many cases the steel has already cracked or is no longer present over a large area.

Component failure

Since the chemical process essentially only damages the reinforcing steel, the concrete can still look completely normal from the outside, while the first cracks form inside until the component fails completely.

Chemical exposures

The chemical connections and background of these so-called exposures are explained in the basics on Wikipedia, among others. While in the so-called carbonatization the concrete reacts with moisture and the CO2 contained in the air, which leads to a reduction in the pH value, which removes the important alkaline protective effect of fresh concrete and instead promotes corrosion Mileu is converted for the steel, the steel is dissolved directly when chloride salt (which is dissolved in parking garages via de-icing agents).

Special case of paved underground car parks

The damage to underground car parks that have a paved surface instead of a floor slab is often even worse, because the spray water enriched with chloride salt seeps away and permanently attaches itself to the concrete.

Concrete investigations

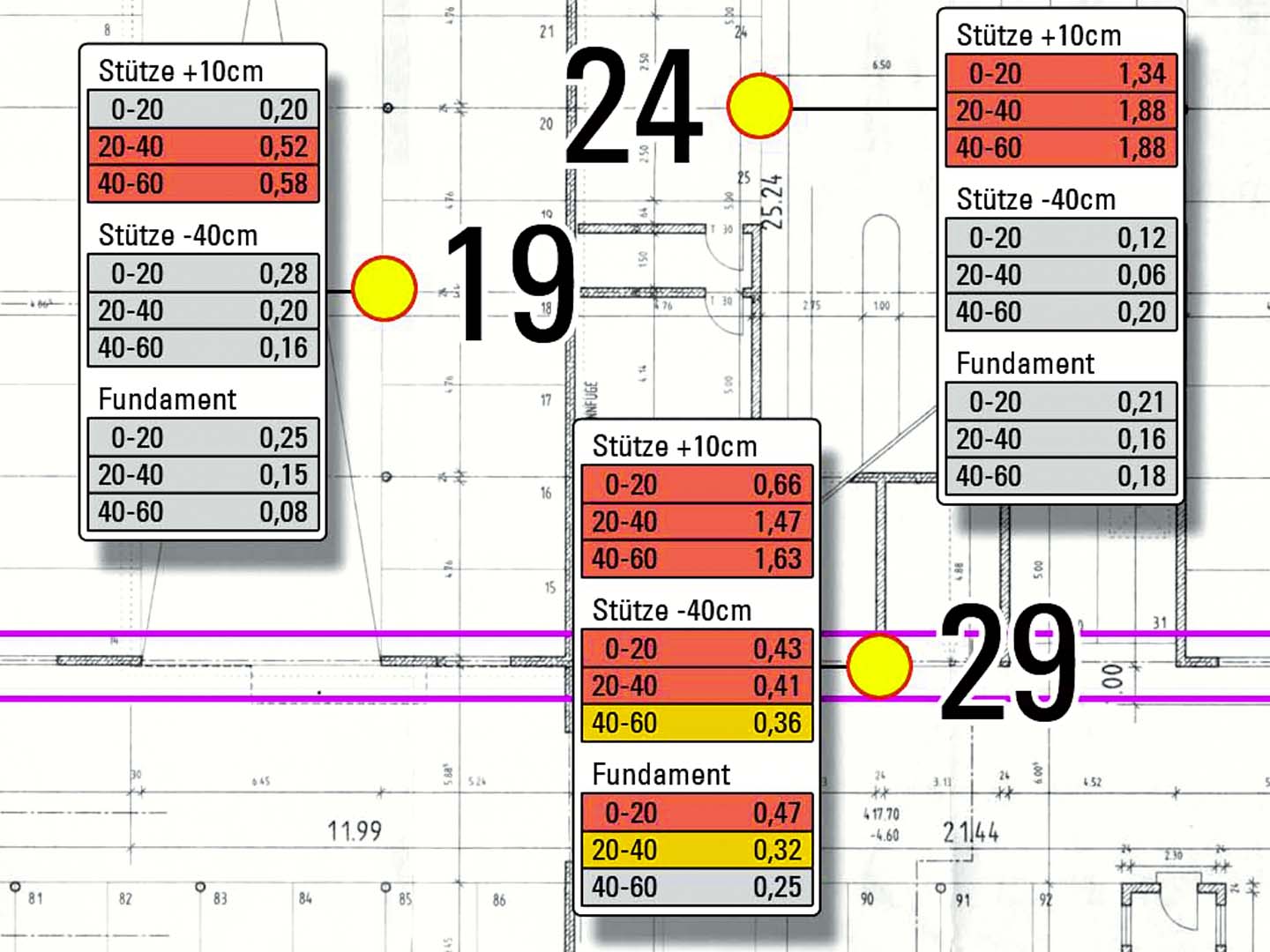

In order to get certainty about the condition of the reinforcing steel, the most effective and economical method is to first randomly measure the chemical penetration depth of the exposures of just a few components and evaluate it in relation to the age of the component. In this way, it can usually be determined with a reasonable amount of effort whether the condition is OK, can be maintained with little effort or is already partially or completely worthy of repair.

For years, ATS has been supporting numerous customers nationwide at various locations from Freiburg to Berlin with the following services in accordance with the building standards of the German Committee for Reinforced Concrete (DAfStb):

For years, ATS has been supporting numerous customers nationwide at various locations from Freiburg to Berlin with the following services in accordance with the building standards of the German Committee for Reinforced Concrete (DAfStb):

- On-site analysis with sampling, laboratory examination for carbonation and chloride entry including an expert planning to describe the situation in a way that laymen can understand, as well as any appropriate ones Renovation options

- Creation of individual service specifications (LV´s) in order to create the opportunity to obtain comparable comprehensive offers from renovation companies

- Anonymous evaluation of repair offers as well as invoice checks for renovation services

- External monitoring and documentation of concrete repair work by your renovation company in accordance with the regulations of the DAfStB

- Inspection of renovated objects and communication of any necessary small maintenance work

- Inspection of your object for any hidden defects before the warranty periods expire